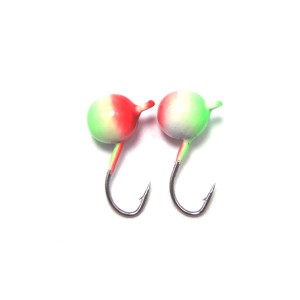

Tungsten Tear Drop Shot Weight

Tungsten Tear Drop Shot Weight

Iinkcukacha

| SIZE (oz) | 1/32 | 3/64 | 1/16 | 3/32 | 1/8 | 3/16 |

| Ubunzima (g) | 0.9 | 1.3 | 1.8 | 2.7 | 3.5 | 5.3 |

| SIZE (oz) | 1/4 | 5/16 | 3/8 | 1/2 | 3/4 | |

| Ubunzima (g) | 7 | 8.8 | 10.5 | 14 | 21 |

Imibala:Ithafa, iShinny Black, iOxiden Matt Black, ithanga eliluhlaza,

Umnyama, Obomvu, uJunibug

Izinto:97% iTungsten

Idyasi:I-Plain & Oxide & Painting

Uhlobo lweRingi:IClip & Eyelet

Ixabiso leyunithi (EXW):US$0.1~$2.0 ngokusekelwe ubunzima kunye nobungakanani

Ixesha lokuhlawula:T/T, Western Union, Paypal, L/C

INKQUBO YEMIM

I-CORE TECHNOLOGIES KELU ine-MIM kunye ne-CNC, zombini kumacandelo ezemidlalo aphezulu.

Ukubumba inaliti yesinyithi (MIM) bubuchwephesha obutshintshayo obudibanisa ukuBunjwa kwePlastiki yeSitofu, ikhemistri yePolymer, iMetallurgy yePowder kunye neMetallic materials science.Singaphuhlisa ukungunda ubungakanani obukhethekileyo obulungiselelwe ubungakanani / imilo okanye ukuvelisa ngokungunda okukhoyo ngokuthe ngqo.ITungsten, iBrass, iStainless Steel inokukhethwa njengezixhobo zeMIM.

Ulawulo lwamanani ekhompyutha (CNC) kukuzitshintsha kwezixhobo zoomatshini ngokusebenzisa iikhompyutha ezenza ulandelelwano olucwangcisiweyo lwangaphambili lwemiyalelo yolawulo lomatshini.Kwaye izinto zayo ezisebenzayo ziquka iTitanium, iTungsten, iAluminiyam, iBrass, iStainless Steel, iZinc njalo njalo.

Iimarike eziphambili:

UMntla Merika, eYurophu, eOstreliya, eAsia

UKUHLOLWA KWABATHENGI