I-Tungsten Dart

I-Tungsten Dart

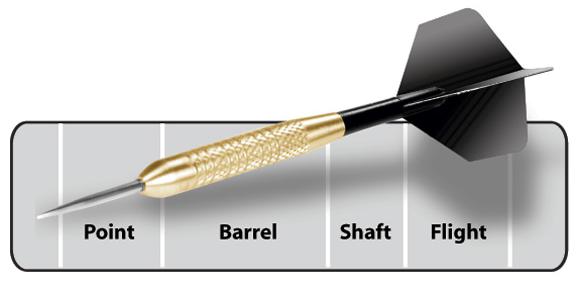

I-Dart yenziwe kwiindawo ezine eziphambili, indawo, umphanda, ishaft kunye nokubhabha.

Imiphanda ngowona mzimba uphambili kwaye iza kwiimilo ezahlukeneyo, ubukhulu kunye nemathiriyeli.

Njengomdaniso obonelela ngevenkile, i-KELU igxile kumphanda kunye nePoint, iTungsten, iNickle, kunye neBrass zombini ziyafumaneka.

I-Brass dart ayibizi kwaye ifanelekile kumdlali wekhaya lokuzonwabisa kunye nomdlalo we-pub ngamaxesha athile.

I-Nickel Silver ineempawu ezifanayo zobhedu kodwa iyaxhathisa.

Umphanda we-tungsten dart uxinene kakhulu, uxinene ngokuphindwe kathathu kunobhedu kunye nesilivere ye-nickel, kwaye iyathandwa ngenxa yobunzima bayo ukuya kumlinganiselo wesayizi okhokelela kubunzima obunzima kubunzima obuncinci.

INKQUBO YEMIM

I-CORE TECHNOLOGIES KELU ine-MIM kunye ne-CNC, zombini kumacandelo ezemidlalo aphezulu.

Ukubumba inaliti yesinyithi (MIM) bubuchwephesha obutshintshayo obudibanisa ukuBunjwa kwePlastiki yeSitofu, ikhemistri yePolymer, iMetallurgy yePowder kunye neMetallic materials science.Singaphuhlisa ukungunda ubungakanani obukhethekileyo obulungiselelwe ubungakanani / imilo okanye ukuvelisa ngokungunda okukhoyo ngokuthe ngqo.ITungsten, iBrass, iStainless Steel inokukhethwa njengezixhobo zeMIM.

Ulawulo lwamanani ekhompyutha (CNC) kukuzitshintsha kwezixhobo zoomatshini ngokusebenzisa iikhompyutha ezenza ulandelelwano olucwangcisiweyo lwangaphambili lwemiyalelo yolawulo lomatshini.Kwaye izinto zayo ezisebenzayo ziquka iTitanium, iTungsten, iAluminiyam, iBrass, iStainless Steel, iZinc njalo njalo.

Iimarike eziphambili ze-KELU:

UMntla Merika, eYurophu, eOstreliya, eAsia